Over the past few years, coordinate measuring machines have become increasingly common in industries that require high-accuracy data and design consistency. These requirements have especially driven the growth of quality assurance in automotive, aerospace, and heavy machinery industries. More and more, clients expect shops to have in-house inspection capacity. When you can perform quality assurance in your own facility, you can promise consistency without delays. You’ll also be able to check problems with machine tools before the error causes you to rework or scrap hundreds of units.

Fortunately, you don’t necessarily have to go out and invest in an expensive new piece of metrology equipment right away. Used coordinate measuring machines can be a sound investment with a better return, depending on your needs. Most metrology instruments can last from twenty to thirty years with the right maintenance, and possibly even longer with upgrades from metrologists like Canadian Measurement-Metrology (CMM).

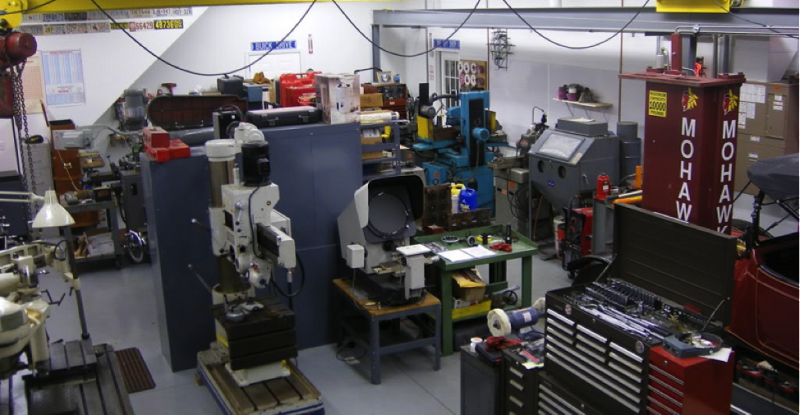

Preowned measuring instruments can be a great way to introduce an internal inspection department, but before you go looking on the market, it’s important to understand what you’re looking for. Audit your requirements: do you produce large parts that are difficult to move to an air-conditioned inspection lab? Are you running checks on every 100th unit or are you checking every component? If you want automated inspection, think about how you’re going to move pieces for measurement.

When you go through a metrology vendor that sells used coordinate measuring machines, Canadian Measurement-Metrology Inc. for example, you’re getting a refurbished and thoroughly tested piece of equipment. You may be tempted to pick up a used coordinate measuring machine at auction, but be warned that the cost of an auction purchase can be deceptive. In addition to a 10 to 15 percent buyer’s premium (paid to the auction house), you will also be responsible for shipping, installing, and calibrating the instrument. There are no guarantees that your purchase will even be operational once it’s on your shop floor unless you go with a metrology dealer. They don’t hide their costs and they refurbish all of the equipment they resell.

Create and list of wants and needs before you take a look at the biggest selection of used CMM equipment in North America. To maximize your investment’s lifespan, find brand names that will be more likely to make replacement parts available. Find out what you’re getting into when it comes to software. It will be easier to find trained operators, or to find online training courses, for brand name software like PC-DMIS. PC-DMIS is compatible with CAD (Computer Aided Design) and works across a wide range of machine controllers. It won’t be difficult to find updates when GD&T (Geometric Dimensioning and Tolerance) standards change. Keep in mind that software can stay relevant for up to a decade, so a recent upgrade on preowned metrology equipment can be a great bargain. When you’re buying preowned, always go with a name you trust.